Profile

Jieying Precision at a Glance

Constant pursuing of technological excellence to manufacture precision plastic & LSR (Liquid Silicone Rubber) components and products. We are a top-tier solutions provider for high performance tooling, unique technology know-how for multi-component and LSR tooling & molding. Specializing in high precision plastic parts and LSR parts utilizing LIM (Liquid Injection Molding) technology, and LSR over-molded components with plastic and metal substrates (machined / stamped / MIM). Our production plants are equipped with state-of-the-art ultra-precision LSR injection machines and equipment in a clean production environment.

- Core team members with average experience of over 20 years in the field

- Specialized in plastic, LSR (Liquid Silicone Rubber) and precision tooling

- High precision LSR & over-molded components using injection molded plastic and metal substrates (machined / stamped / MIM)

- Ultra-precision tooling up to 0.005mm in accuracy

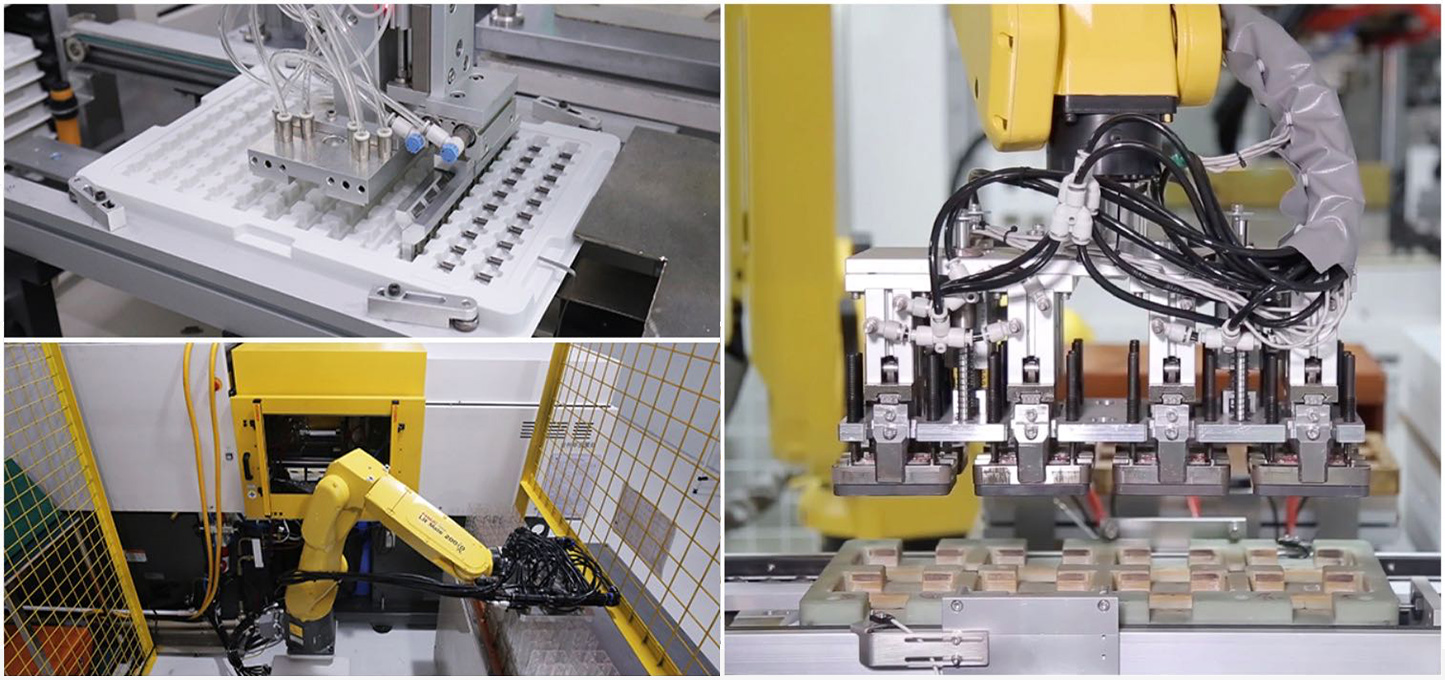

- Equipped with state-of-the-art ultra-precision molding equipment

- Clean room production environment with highly automated production processes

- Plant area: 26,000 m2

- Employees: over 900

-

20over 20 years of experience

-

0.005tooling up to 0.005mm in accuracy

-

26,000Plant area: 26,000 m2

-

900Strong work force of over 900 employees

Services

Our Services

-

Early Involvement in Initial Project Discussion

Early Involvement in Initial Project Discussion -

Part Design Optimization

Part Design Optimization -

Material Selection and Design Advice

Material Selection and Design Advice -

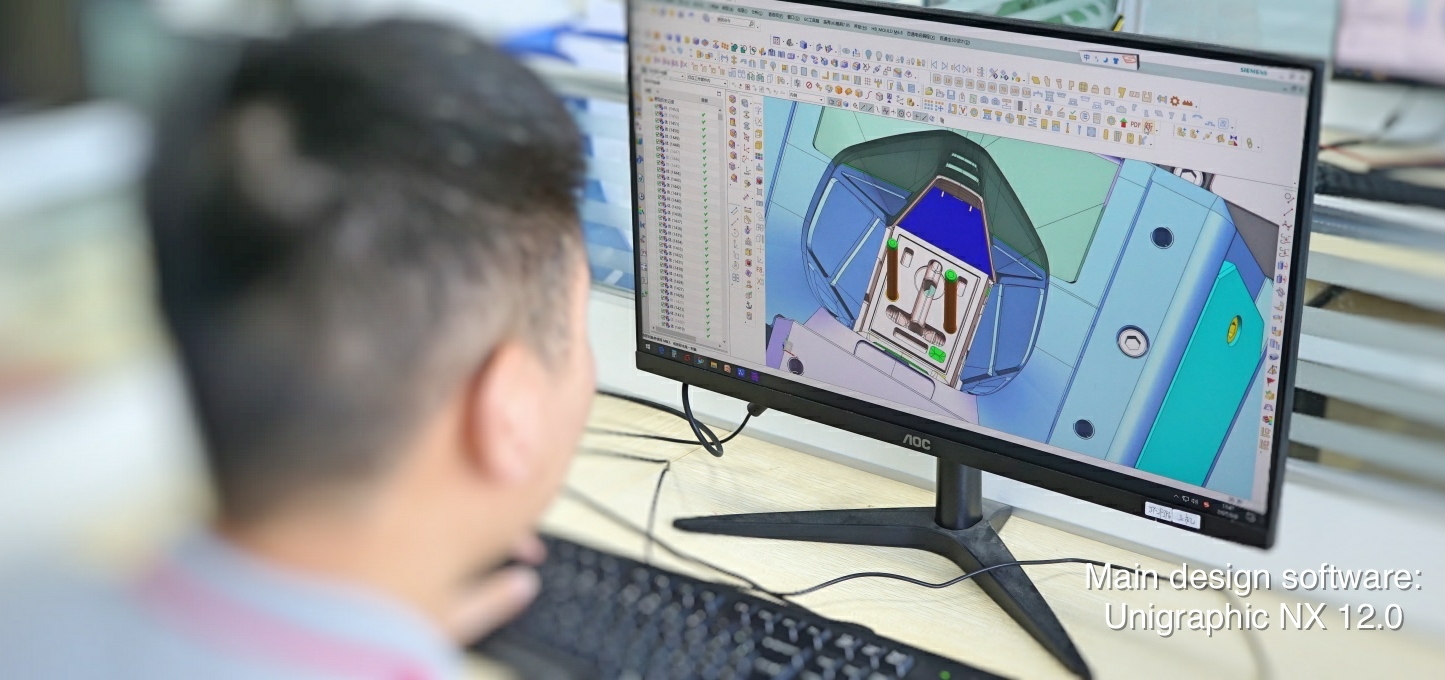

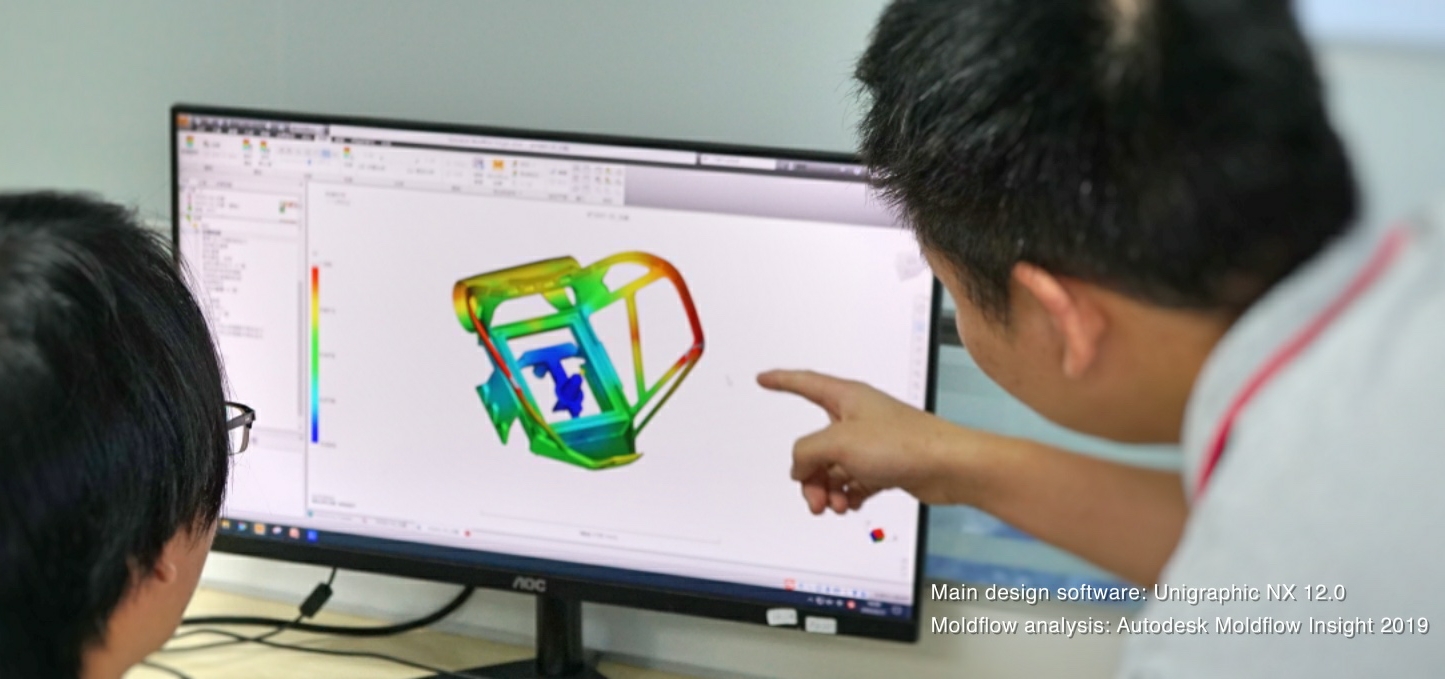

R&D and Mold Analysis

R&D and Mold Analysis -

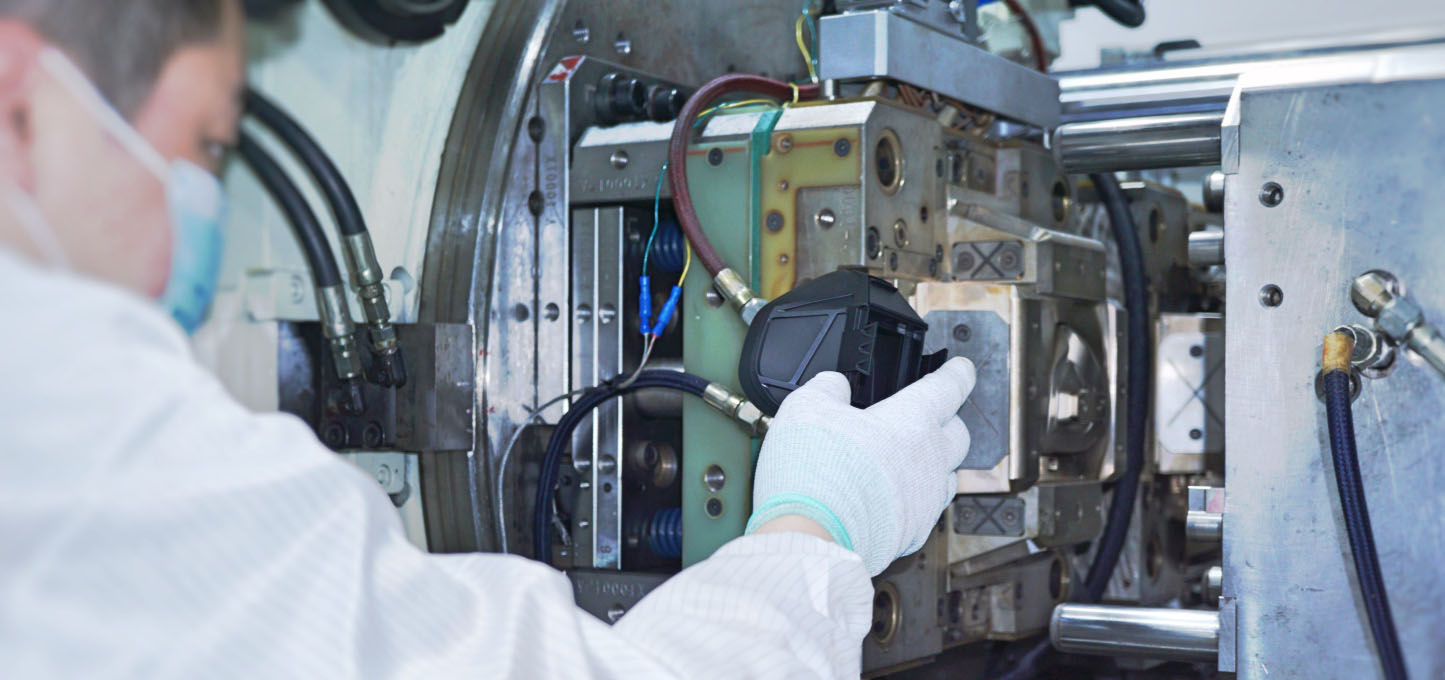

Prototyping and Pilot Production

Prototyping and Pilot Production -

Customized Process and Quality Control System

Customized Process and Quality Control System -

High-Precision and High Volume Production by Applying Advanced Technology in Process & System

High-Precision and High Volume Production by Applying Advanced Technology in Process & System

VISION & MISSION

Vision & Mission

-

Our Vision

- To be the leading supplier for ultra-precision plastic & LSR tooling and components in the region

- To be the preferred innovative & technical tooling, plastic and LSR solution provider

-

Our Commitments

- Superior Quality

- Speed to Market

- Scalability – High Volume Production

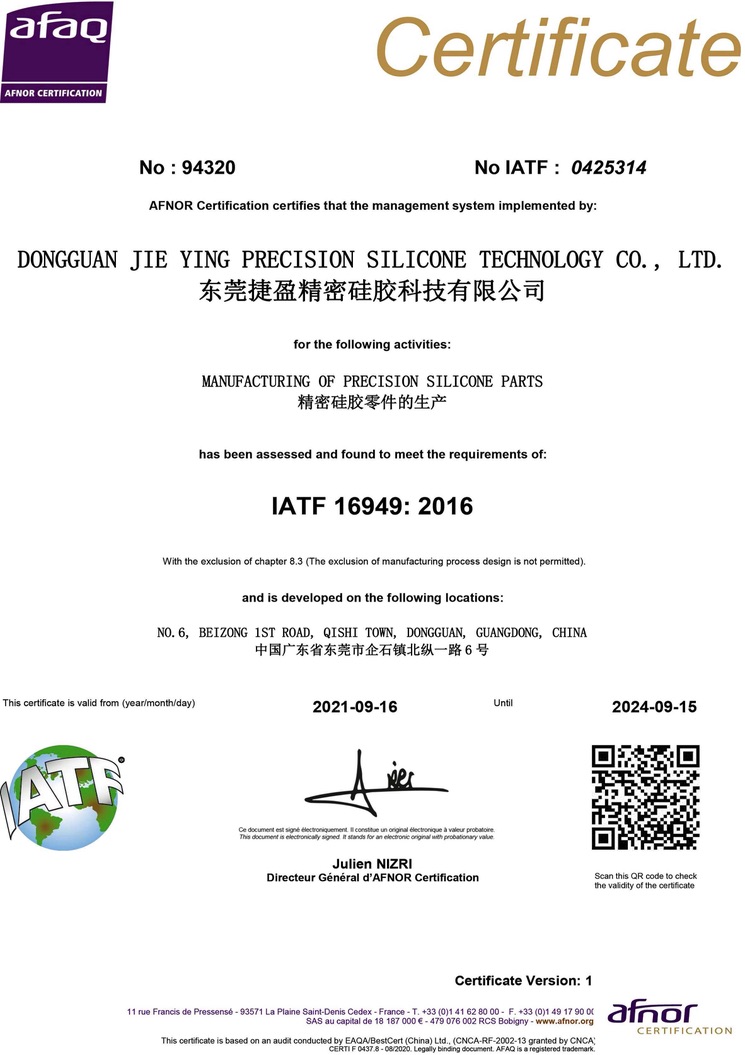

OUALITY SYSTEM

Quality System

-

Certifications●ISO 9001:2015

Certifications●ISO 9001:2015

●ISO 14001:2015

●ISO 13485:2016

●IATF 16949:2016

-

Quality Policy●Be Innovative

Quality Policy●Be Innovative

●Excellence in Quality

●Quality & Service Oriented

●Total Customer Satisfaction

-

Environmental Policy●Promote environmental awareness

Environmental Policy●Promote environmental awareness

●Enhance effectiveness of reuse and recycling

●Abide environmental regulations

●Improve environmental quality